Swift Manufacturing & Engineering QC Lab and CNC CMM

At Swift Manufacturing & Engineering we specialize in machine shop, assembly, and engineering services. We have a 14,000 sq.ft Manufacturing Space – With an additional 4,000 sq.ft. of Engineering and Administrative Office Space. Below you will find a list of our equipment and software capabilities.

The list below is related to contract manufacturing and in-house capabilities. If you are looking to find out more about engineering services, please shoot us a call!

We are growing, so if it isn’t on the list today, it may be tomorrow. We have a commitment to staying on top of, or in front of, technology. In order to compete in our state, nationally, or globally, we need to invest in new technologies. This includes strong investments in computerized equipment, software, robotics, and tooling.

We need to embrace technology to keep our edge in the industry and serve not only our customers well, but our staff well too. The landscape of manufacturing is ever changing, and there has never been a faster paced evolution of technology than right now, and that is anticipated to increase as time goes on. We keep an open mind so that we can absorb new thinking in industry supply.

Capabilities

Software

- DropBox

- MS Office

- SolidWorks

- PhotoView

- CamWorks – Full 3D Multi-Axis Surfacing Package

- AutoCAD

- Adobe Photoshop CC

- Adobe Illustrator CC (We can take your art and turn it into toolpaths!)

- Draftsight

- ZBrush

Equipment

- Haas VF-2SS CNC Mill w/ 4th Axis and Renishaw Probe – 30″ X 16″ X 20″

- Haas VF-4SS CNC Mill w/ 4th Axis and Renishaw Probe – 50″ x 20″ x 25″ (1270 x 508 x 635 mm)

- Haas DT-1 CNC Mill and Renishaw Probe – 20″ x 16″ x 15.5″ (508 x 406 x 394 mm)

- Haas ST-10Y CNC Lathe (Y Axis Live Tooling with Bar Feed)

- Mazak Super Quick Turn SQT-18MS CNC Lathe – Live Tooling

- Tree 1060 ZPS CNC Mill – 40″ X 25″ X 30″

- Fadal CNC Mill – 25″ X 16″ X 18″

- Milltronics VM15 CNC Mill – 25″ X 16″ X 18″

- Laguna Swift 4′ X 4′ CNC Wood Router

- Brown and Sharpe Knee Mill

- Grizzly 13 X 40 Engine Lathe

- HEM Automatic 25 HP Horizontal Band Saw

- Cincinnati Surface Grinder [2 Additional Surface Grinders]

- Drills

- Vertical and Horizontal Band Saws

- Cut-Off Saws

- Grinders

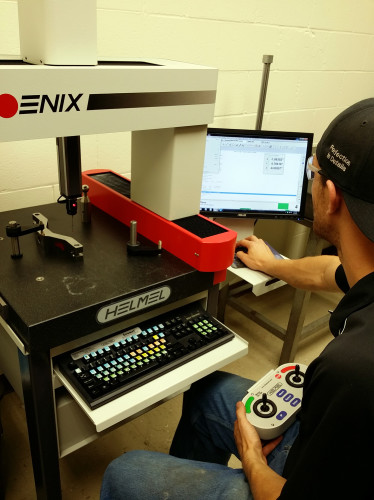

Quality Control

- Helmel CNC CMM [Traceable to NIST]

- Optical Comparator

- 6 Calibrated Surface Plates

- Numerous Calibrated Digital Height Gages w/ SPI [Up to 24″]

- Digital Calibrated Mics [0.0001″ Resolution / 0.0001 Repeatability]

- Digital Calipers up to 18″

- Calibrated Gages Blocks[Set(s)] and Pins [Up to 1″ Diameter]

- Custom Gage Block and Pin GO/NOGO Gage Program with Certifications [Please call for information about our programs.]

- 2A/2B, 3A/3B Thread Gage Sets w/ Certifications and Calibrated

- Custom Thread Gage Program with Certifications [Please call for information about our programs.]

- In Process Renishaw Probing [Repeatable to 0.0002″]

- Depth Mics [Up to 32″ Depth / 0.0001″ Resolution]

- Inside Mics [UP to 32″ / 0.0001″ Resolution]

- Bore Gages

- Tool Touch Off [Repeatable to 0.0002″]

Swift provides CNC machined components, custom parts, metal manufacturing and assembly for our customers worldwide. Our machining services include:

– CNC machining services

– CNC milling services

– CNC cutting services

– Grinding services

– Drilling services

– CNC turning services

We are a Machine Shop proud to provide CNC machining services to our local Madison WI community and Wisconsin!